Did you realize that you can’t stop pressure washing without completely turning off your machine? You certainly can, but you shouldn’t.

Hazardous pressure can build up if you move away to take a phone call, chase your dog, or speak with your neighbor without a pressure washer unloader valve.

The engine continues to run after you remove the spray wand trigger, but no pressure is released. This accumulation of excessive pressure can seriously harm your machine.

If you use your pressure washer frequently, an unloader valve is a must-have accessory. By controlling the system pressure with this instrument, you may avoid costly repairs or replacements.

How does a pressure washer unloader valve work? Let’s find out!

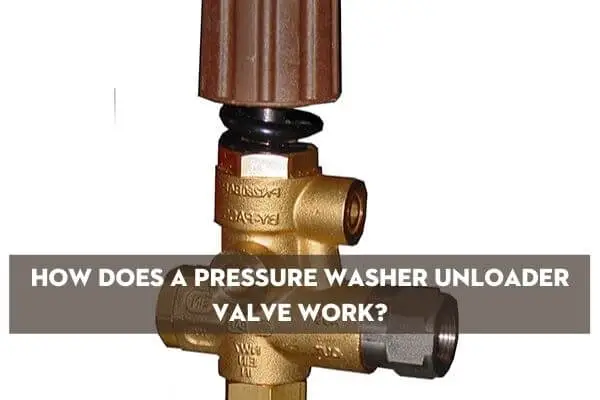

What Is A Pressure Washer Unloader Valve?

An unloader valve is essentially a safety switch. It transfers pressurized water from the pump’s output side to an inlet or a water tank, sending it through a by-pass. While the pressure washer machine is idling, this procedure depressurizes the water and prevents pressure from building up.

How Does A Pressure Washer Unloader Valve Work?

Before it exits the exit hose and pressure nozzle, the unloader valve acts as a gatekeeper for passage pressure water within a pump. During periods of non-use, unloader valves automatically regulate when water flows into the nozzle or recirculates back into a pump.

When the pump is not in operation, the water inside it forms a closed loop, with no “new” water able to enter. The unloader valve closes closed circulation and allows new water to enter the system once the operator releases pressure.

In contrast to impulse pumps, which only work on or off, pressure pumps employ positive displacement technology, which essentially means that water flows through them continually.

How does an unloader valve work? An unloader valve is required for positive displacement pumps because it prevents them from building up negative internal pressures.

Check out this video for the best view on pressure washer bypass valve:

What Are Types Of Pressure Washer Unloader Valves?

There are two kinds of unloader valves.

Depending on whether your unloader valve is a pressure-actuated unloader valve2 or a flow-actuated unloader valve, your unloader may operate in one of two ways.

Unloader Valve with Pressure Actuation

The gun’s valve is open when you push the trigger using a pressure-actuated unloader valve, discharging the water via the nozzle.

This reduces pressure on the unloader valve, allowing the water from the pump to flow directly to the nozzle.

The pressure on the unloader valve increases when the trigger gun’s valve is turned off by releasing the trigger, forcing it to unload or recirculate back to the reservoir.

Unloader Valve with Flow Control

The valve system functions in the same way with a flow-actuated unloader valve.

The unloader, on the other hand, is controlled by the flow rate.

A piston is utilized instead of spring in this scenario, and if the flow is reduced, the unloader will begin recirculating the water back to the pump intake or tank.

Why Do I Need A Pressure Washer Unloader Valve?

Safety

Surfaces, adjacent items, and even persons who come into contact with pressure washers can be damaged by excessive pressure. While water isn’t usually thought of as a harmful material, it may cause damage to the skin, eyes, ears, and other parts of the body if it is exposed to too much pressure.

You can use the unloader valve to reduce or completely stop the pressure. Furthermore, you may complete it fast, which means you have a far lower risk of causing severe harm. If you have to go a few feet back to the pressure washer to turn it off, it is far more probable that someone may get hurt.

Ease of Use

It not only makes the pressure washer safer for users and anyone close, but it also makes it easier to use.

You won’t have to constantly return to the switch to modify the pressure or turn the water on or off. Instead, you can occasionally alter the pressure to give yourself additional options.

You can wash more surfaces with less worry if you have a more comprehensive pressure range.

The usage of an unloader valve, on the other hand, may result in the machine receiving a greater PSI than it was designed to withstand. This is because the water may need up to twice as much pressure to return to the machine as it does when it is flowing correctly.

This can cause significant issues with the equipment and an increased danger of the nozzle or pressure washer exploding, posing additional safety hazards.

FAQs

Why isn’t the pressure in my pressure washer increasing?

Disconnect the high-pressure line from the pump and connect the garden hose to the faucet. If this does not happen, there is a problem with the internal pump. If this happens, a blockage is most likely in one of the attachments, such as the high-pressure hose, cannon, wand, or nozzle.

What causes a pressure washer to malfunction?

An improper nozzle or a worn-out nozzle is the most common reason for low pressure in a pressure washer. However, check that water is getting to the equipment properly as well – a hose running up a slope can cause water pressure to be delayed. When you see any worn or damaged nozzles, replace them right away.

When a pressure washer pump freezes, what happens?

When a pressure washer freezes, it may be damaged. Water expands and can cause damage to the pump, as well as some pipelines and valves. The hosepipe is made of rubber, which may expand somewhat, but rubber is considerably stiffer than plastic and can be damaged or even ruptured when cold.

Conclusion

It’s important to consider whether you want to use an unloader valve even if you don’t have a pressure washer yet.

How does a pressure washer unloader valve work? Now you know the answer. It’s critical to understand how your washer’s unloader valve operates. Making sure of how an unloader valve pressure washer works will benefit both your health and your investment.

Related Post