Because they can readily remove accumulated filth in a matter of minutes, pressure washers are found in many households and cleaning services. The pressure is the key, as it washes even the most durable components away from the surface.

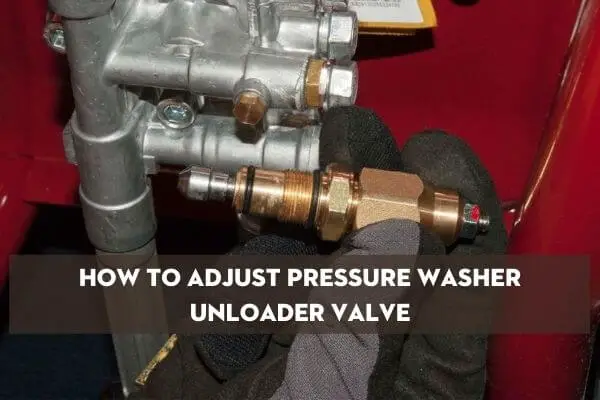

The washer’s component unloader valve is critical in this respect and serves a critical role, although it is not easy to operate. The reason for this is because you’ll need to learn how to regulate the pressure washer’s unloader valve.

Don’t worry. Now we’ll go through how to adjust the unloader valve in detail and give you an outline of what it is.

What Is The Function Of The Unloader Valve?

A compressor unloader valve is a small component that is around 4-5 inches long and wide. It is responsible for releasing trapped air inside the tank and allowing the motor to restart. One of the most common air compressor problems is a faulty unloader valve. The accumulated pressure may be enough to prevent the motor from restarting if the trapped air cannot escape.

The type of unloader valve found in an air compressor is determined by the model and size of the machine. Some are controlled by a toggle switch on the pressure switch’s side. Others feature a built-in valve beneath the pressure switch.

How Does An Unloader Valve Work?

The functioning of the unloader is straightforward. When the trigger is pulled, a valve in the gun opens, allowing water to flow from the pump’s output side to the gun via the hose.

The valve shuts, the unloader is triggered when a rise in pressure or a reduction inflow releases the trigger.

The unloader redirects water flow from the pump’s exit side to the input side, causing water to flow in a loop back to the pump at almost no pressure rather than to the nozzle at working pressure. Flow can be returned to the pump intake or diverted to a float tank or other reservoir.

How To Adjust Pressure Washer Unloader Valve

Step 1

Check to see if the engine or motor is spinning at the correct RPM. Before a load, the RPM is 3700, and after a load is 3400.

Step 2

Replace the spray nozzles on your pressure washer with new high-pressure washer spray nozzles with the correct orifice size.

Step 3

Spin the black plastic pressure adjustment knob off and remove the nylock nut from the top of the unloader valve.

Remove the thin washer as well as the spring. A threaded piston rod with two locking nuts should now be visible.

Step 4

Tighten the two nuts with wrenches three threads from the bottom, then replace the spring washer and black adjustment knob.

Attach a pressure gauge assembly to the pump and high-pressure line so you can view it while triggering the pistol and tightening the adjustment knob.

Turn on the water and, before starting the machine, pull the trigger on the pistol until the pump is empty of air and only water is flowing out.

Trigger the pistol and tighten the spring while keeping an eye on the gauge. If the nuts are placed too low, you’ll reach a point where you can attain maximum pressure with the pistol engaged while tightening down on the spring, but the pressure will only rise 6 to 9% when you let off of the gun trigger.

The nuts should stop the adjustment knob at this point. With the trigger engaged, you won’t receive any more working pressure if you crank down the spring more, but if you let go of the trigger, you’ll get a dangerously high spike pressure that might destroy your pump.

When you let off the trigger, you don’t want more than a 10% increase in pressure. So, for example, when you let go of the trigger after setting the operating pressure to 3500 PSI, the pressure should not exceed 3850 PSI.

Step 5

Engage the gun trigger and let go around 20 times to let the unloader break-in. This will prevent the unloader valve from becoming stuck.

Step 6

Continue to remove the adjusting knob, washer, and spring while the machine is running and move the nuts higher or lower on the piston rod.

Keep doing it until you bottom out the adjusting knob on the two nuts, you get maximum pressure with the gun engaged and the minor spike when you release the trigger.

When you’ve found this area, remove the adjusting knob, washer, and spring, then use a set of wrenches to tighten the two nuts together tightly, then reinstall the spring, washer, and adjusting knob.

Re-check the pressure and spike pressure by cranking down the spring until it bottoms out on the two nuts. If everything is still in working order, screw the nylock nut onto the top of the piston rod until the rod is barely through the nylon, then replace the cover on the adjusting knob.

You may now change the pressure when the pistol is engaged by twisting the adjustment knob between the two bolts and the nylock on top. However, if you modify the unloader without the pistol loaded, the trigger components will move forcefully when the rifle is loaded, potentially damaging the unloader.

Check out this video if these steps confuse you:

Why Do You Have To Adjust The Pressure Washer Unloader Valve?

Pressure washers have a wide variety of pressure levels. Some may have pressures of up to 3500 PSI, which is quite high and may not be suited for some items, like your automobile. As a result, you must exercise caution or risk causing damage to your vehicle.

On the other hand, flooring systems generally demand more pressure since they can resist it, and the amount of filth they may contain may merit it. It’s a good idea to test the pressure on a tiny area initially, just to be sure. The abrupt pressure increase can be harmful, causing damage to property or injuring people.

Additionally, the appropriate spring tension on the valve must be achieved to guarantee maximum pressure when the spray cannon is triggered and minimal pressure rise when released.

You can wash vehicles, screens, and furniture with the most pressure washers by lowering the pressure. Your pressure washer will work to its maximum capacity if the unloader valve is set correctly. As a result, you must understand how to set the unloader valve on pressure washers properly.

Conclusion

Now you know how to adjust pressure washer unloader valve. When you first read the stages, this may be a rather tricky task. However, once you’re in front of your pressure washer and doing it, it’ll be a lot simpler. It won’t be that tough to discover how to adjust the unloader valve on a pressure washer and try it out for yourself. In reality, it will appear to be an easy activity that anybody can complete.

That said, we strongly advise you to have this guide by your side when working on your pressure washer so you may use it as a reference while making the actual unloader valve adjustment. That will make things a lot easier and faster.